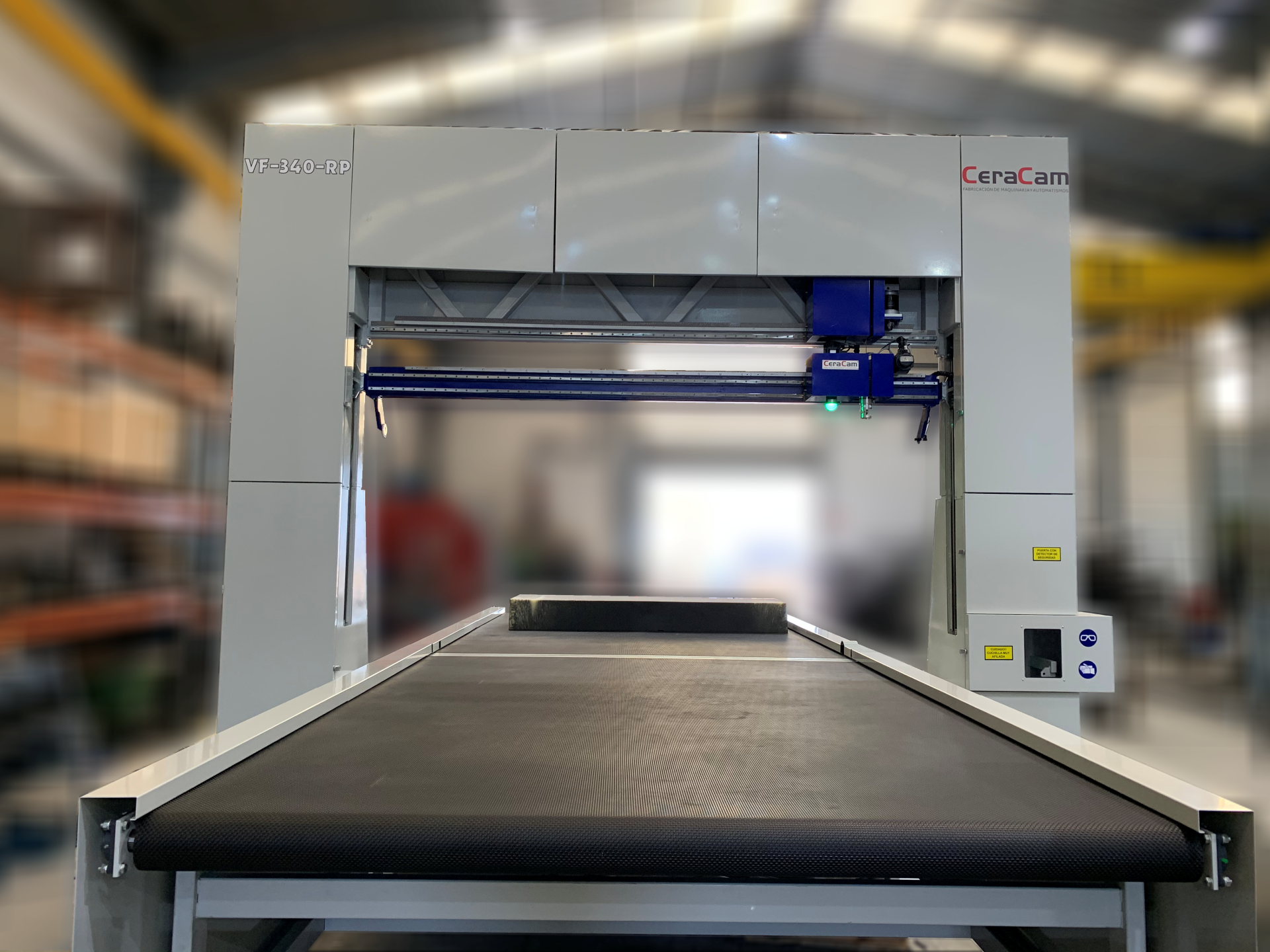

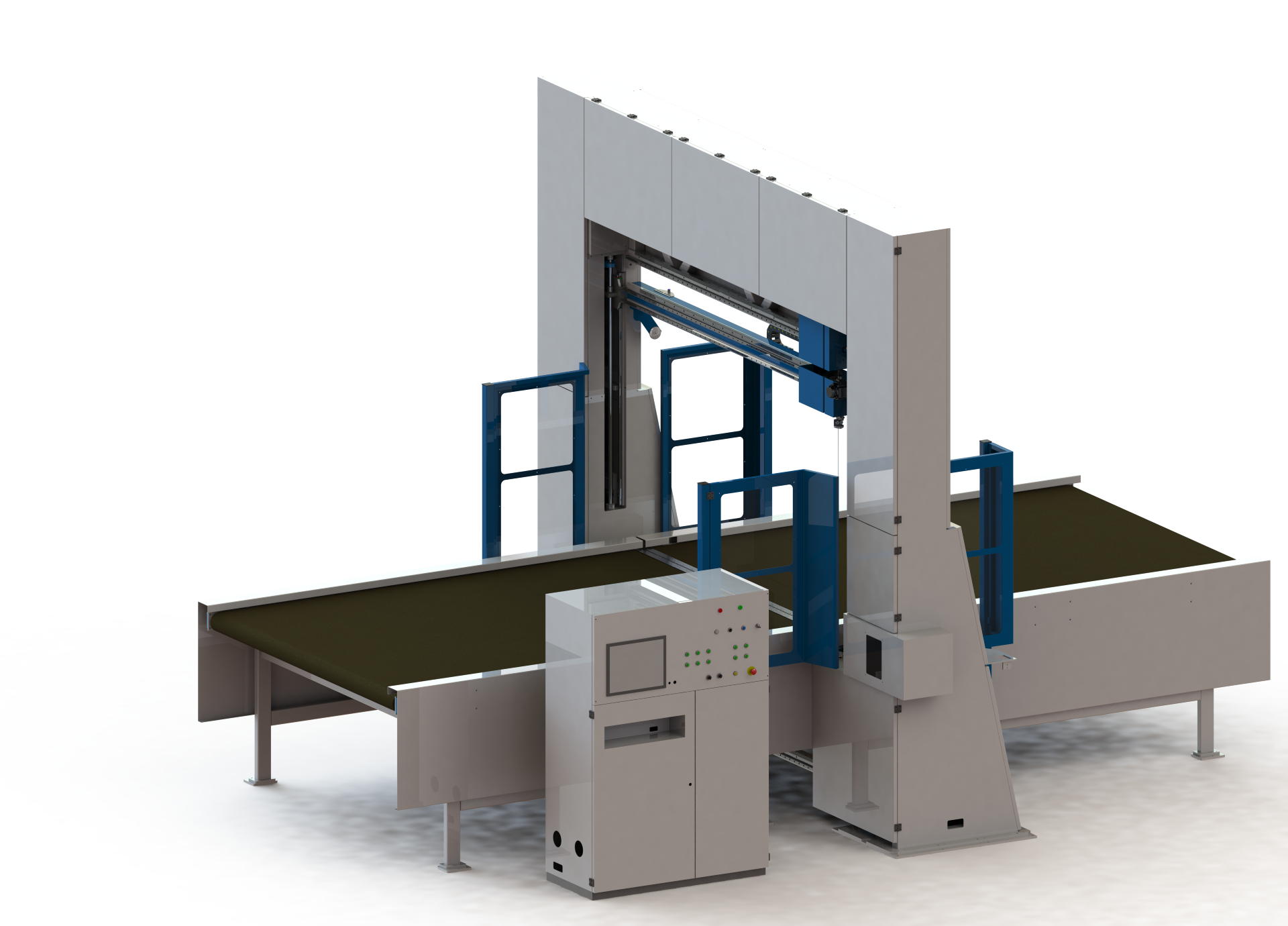

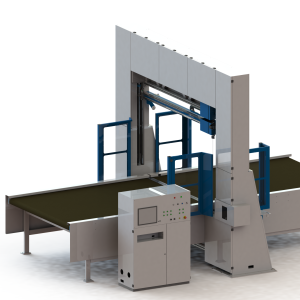

Our vertical foam blade contour cutter is manufactured following the highest quality standards of DANLUK ENGINEERING, rigorously designed and manufactured in our facilities by our team of engineers to make this a cutting-edge machine in its category.

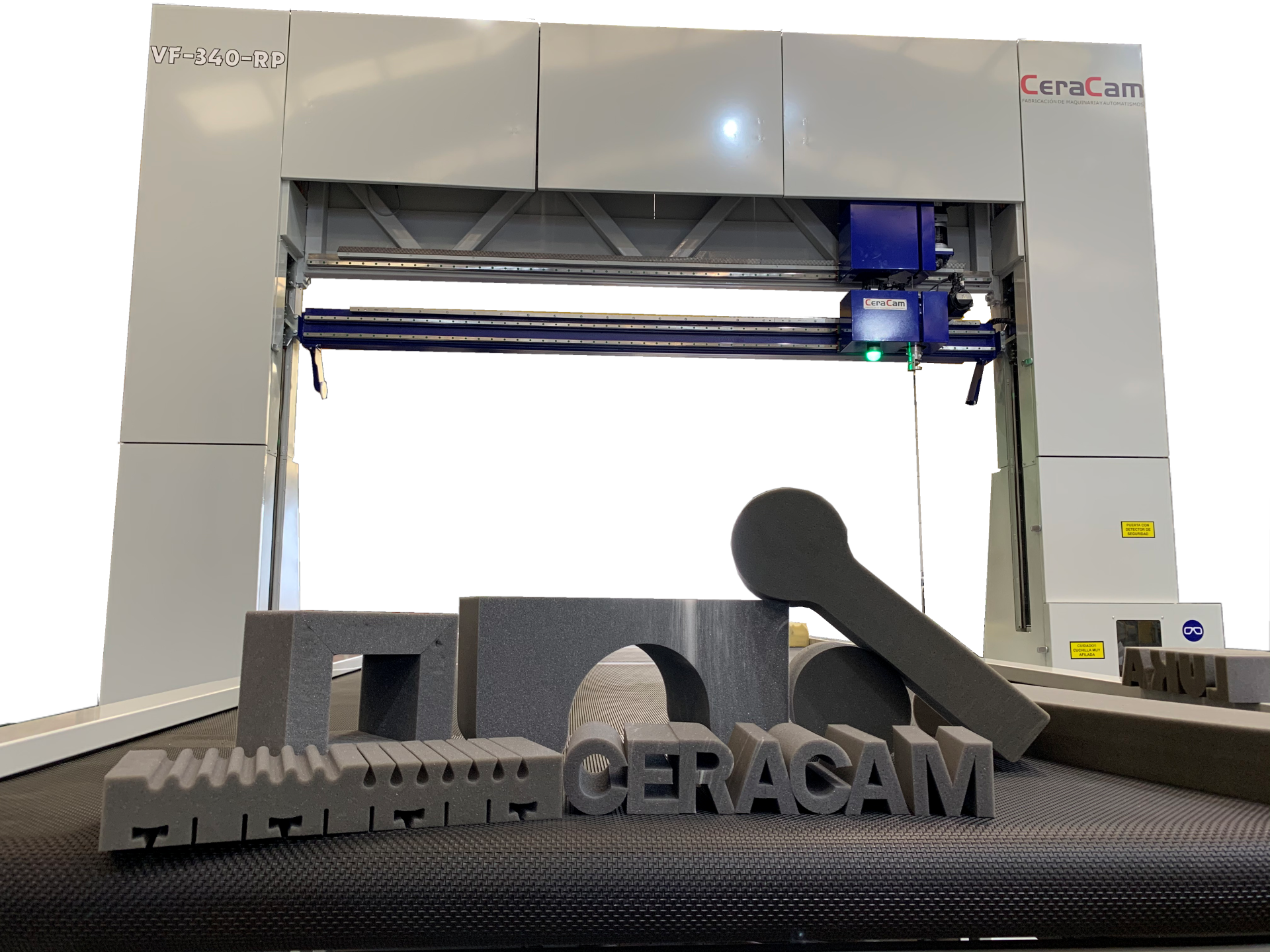

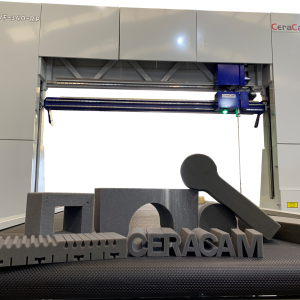

The VF-350 vertical cutter brings together all the most advanced technological and mechanical qualities to offer extraordinary performance. An extremely powerful machine to take cutting production to the highest level. Designed to cut contours with the endless blade vertically and to be able to create figures and shapes both in whole block or laminated block.

Also, ideal for cutting contours and shapes in fiber sheets, felt, foam, etc. on a large scale. It has available as an option a conveyor table of up to 10 meters for loading at the inlet, where different layers of the material to be cut are placed. The versatility of the Cad drawing software facilitates the programming of very long cutting programs, which means that the machine starts to cut at high speed and that countless cut pieces come out of the output, multiplied and ready for their next process.

Toothed or sharp blade ensure dustless and precise cutting. It incorporates a sharpening device for the toothless blade and a pneumatic tensioner with which the adequate and constant tension is achieved at all times during the cutting process. The central head automatically approaches the material to be cut, achieving maximum blade rigidity and allowing cutting at the highest possible speed without losing cutting precision.

The new Cad Drawing Software is designed to be intuitive, step by step and easy to learn. Make drawings in .dxf or .dwg as well as import them from other drawing software. It is the most dynamic on the market, it allows you to create infinite cutting programs at the same time, scale the pieces to optimize the material, infinite geometric applications to enhance the drawing, allows you to generate the cutting path automatically or manually, choose the cutting direction, the entry and exit point, the cutting order between pieces, avoiding the pieces during movements so that the already cut piece is not affected, indicating to the machine at which points (manually or automatically) it has to make the recoveries (turns of +/- 360°) so that the pieces are not marked. Another very important point is the nesting application with which the software, completely automatically, places the pieces to be cut inside the block looking for the most optimal options and thus managing to take advantage of the greatest amount of material possible.